Are you overwhelmed with how to customize your candy pads?

For example, the choice of Layer thickness, the difference in material color, and the brand printing print

Don’t worry, follow our ultimate guide to help you custom your branded candy pads.

Table of Contents

Step 1: Choose the color of the base buffer paper

We have four color options for candy pads: white, brown, black and gold.

White is the color that best presents the brand’s printed logo.

Brown and black are often used for cushioning the inside of chocolate gift boxes

Gold is a favorite color for some festive occasions and some countries

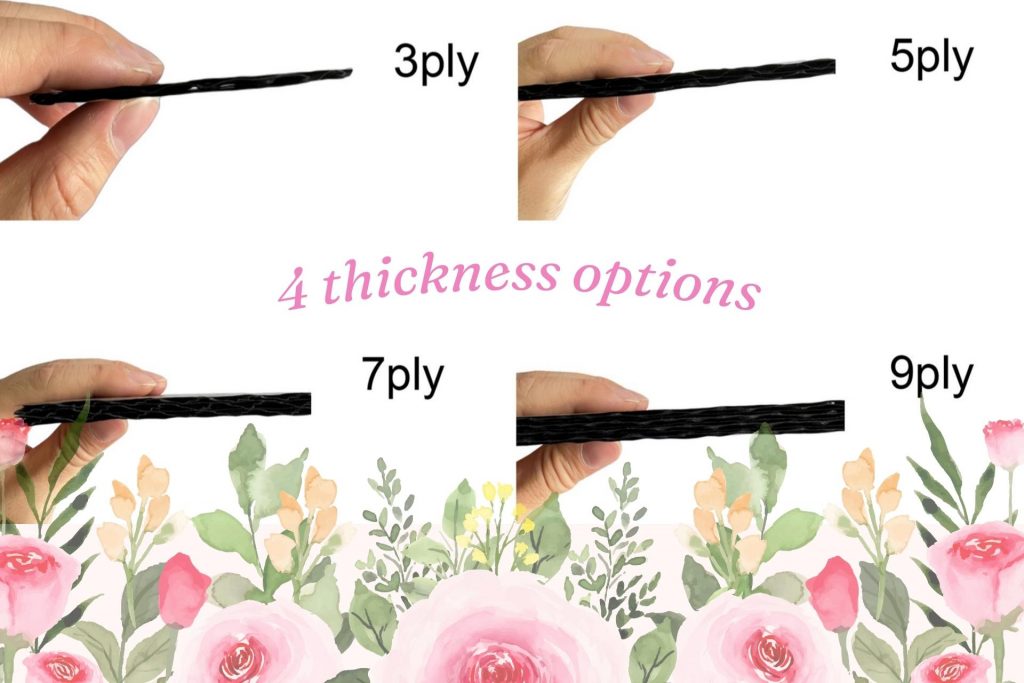

Step 2: Candy Pads Choose Thickness

We provide 3ply, 5ply, 7ply, and 9ply candy pads with different thicknesses for your choice.

Thicker candy pads will provide better protection. If your product is fragile, such as chocolate or cookies, we recommend that you choose a 5-ply or thicker candy mat.

Step 3:Confirm custom candy mat size and shape

We recommend that the candy pads be 1-2 mm smaller than your chocolate box or jar.

The shape of the product we can follow the size and shape of your gift box or tin can packaging

Step 4: Printing candy pads logo

We can print to your logo colors or send PDF AI and CDR files

Choose logo printing style

You can specify the size, position and color of the printed logo

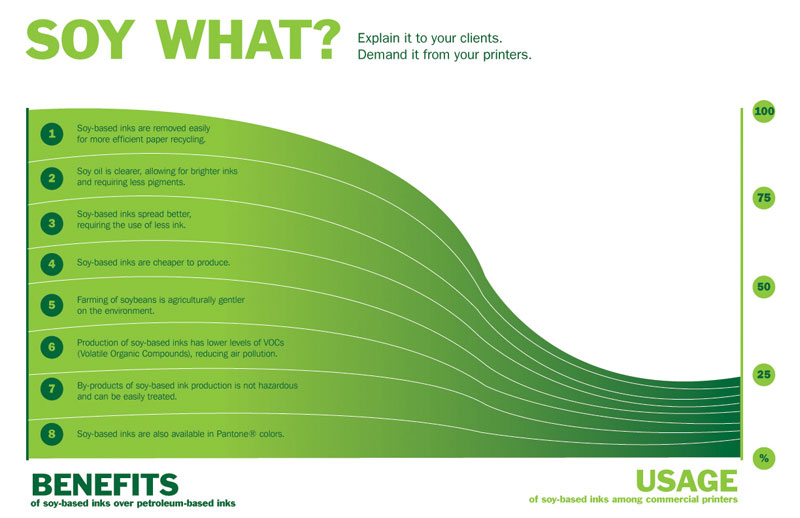

Step 5:Selecting food-safe soy inks

Soy ink is made from soybeans. Compared to traditional petroleum-based ink, soy-based ink is accepted as more environmentally friendly. While slower to dry than many inks, it provides more accurate colors and makes it easier to recycle paper.

Soy ink is not easy to migrate, and the safety of food snacks in the box is further guaranteed

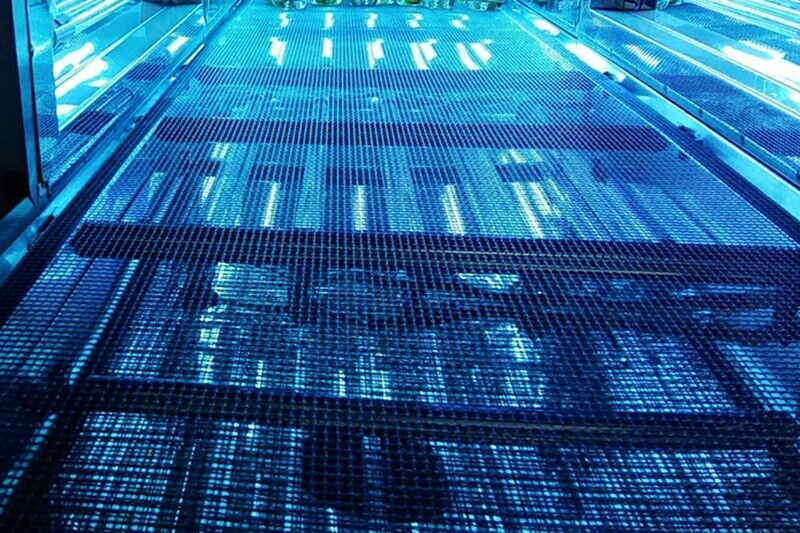

Step 6:≥48H UV Disinfection

We adhere to each batch of UV disinfection ≥ 48h. Ensure the destruction of common bacteria and E. coli. Each batch of products is submitted to authoritative mechanisms.

- Coliform group

- staphylococcus aureus

- Naturally occurring toxins

Step 7:QC QA

Quality inspection of the finished product is an essential process

Weeding out some bad printing and cutting as well as broken and extruded abnormal products caused by turnover in production

Ensure that each candy pads is perfectly presented to the consumer

Start your custom candy pads project

I think you already know how to customize your candy pads. It’s time to start your project. Luckily you found a paper cushion pads manufacturer, a professional manufacturer of custom candy pads. Please contact us anytime to start your custom candy pad project.